Main Benefits:

The Radial+Axial+Radial Technology

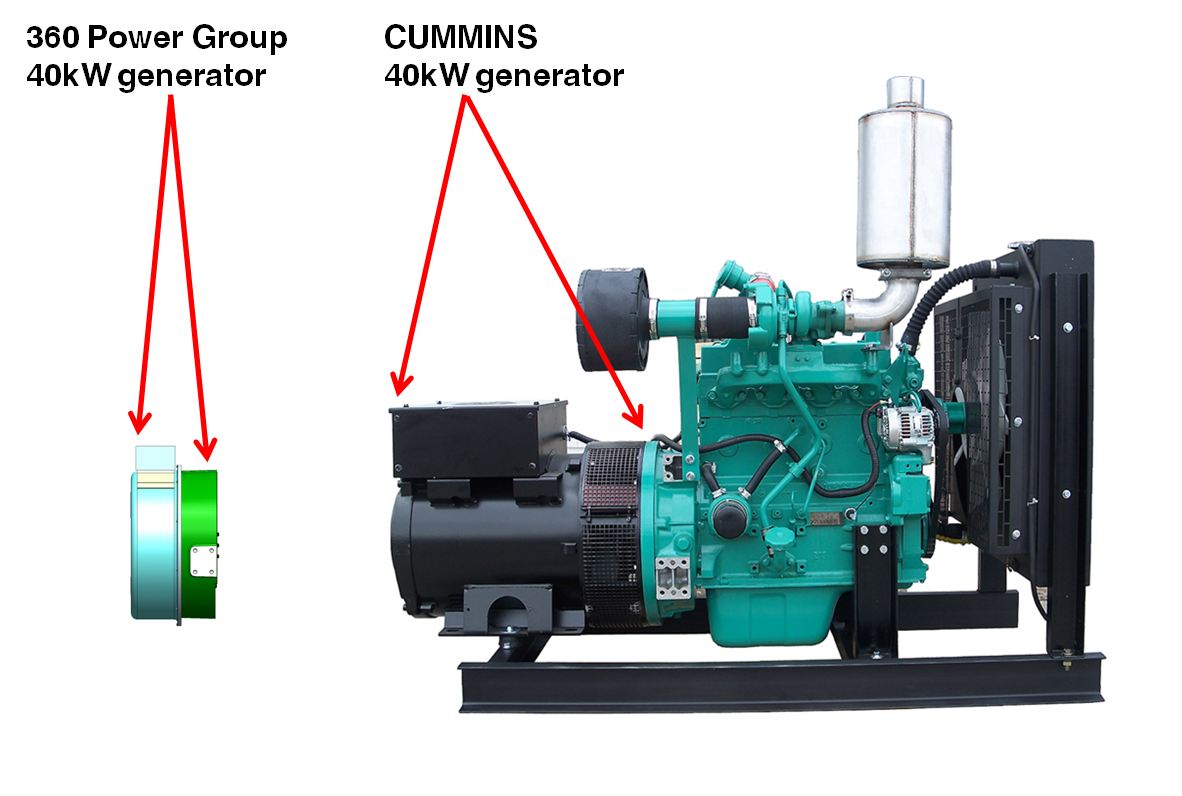

The 360 Power Permanent Magnet Machine is a unique combination of motor technologies that creates a new category. It is a combination of Radial Flux PMA, Axial Flux PMA, Toroidal Alternator, Dual-Rotor Alternator, and Transverse-Flux Alternator.

The machine design uses these technologies in a manner useful for compact motors or engine-driven variable-speed, variable-frequency, high efficiency generators by employing a three-phase coil pattern on the electrical side.

It is well-suited to being larger in diameter than long axially, so axial space next to an engine, when used as a generator, is relatively small. The unique design incorporates a modular component approach that ensures low-cost manufacturing and maintenance.

Mechanically, its rotor/stator arrangement is air cooled and, as a generator, is suitable for both direct drive and shaft drive configurations. For direct drive, the machine is bearing-less with its stator mounted directly on the engine bell housing, and its rotor directly mounted to the engine flywheel. For shafted arrangements, the generator can be face-mounted or foot-mounted, and driven by couplings, splines, sheaves and v-belts, and similar shaft attachments.

Unlike other engine-driven gensets that always run at a fixed speed to maintain constant frequency, the speed of the 360 Power Group system is varied according to the instantaneous load demand. An advance power electronics converter and load-following control system varies the engine speed to achieve the lowest fuel consumption rate for any load.

The generator voltage and frequency naturally change with speed and load, but the power electronic interface maintains constant voltage and frequency output. This increases efficiency since the speed for the lowest fuel consumption is used at each load. Thus, as a system, the overall energy efficiency and fuel savings is maximized.

The 360 Power Group generator is very scalable from small to large size; same if used as an electric motor. We are currently looking at applications from 5kW to 10MW+ using the same basic design.